We have completed the supply, installation and commissioning phase of an Online Monitoring System for 30 rotating equipment for a client in the metallurgical area.

The system in general allows us to establish predictive maintenance by analyzing vibrations and state variables in rotating machinery such as compressors, pumps, fans, motors, etc. avoiding any unforeseen stoppage due to failure, thus obtaining more reliable and available equipment.

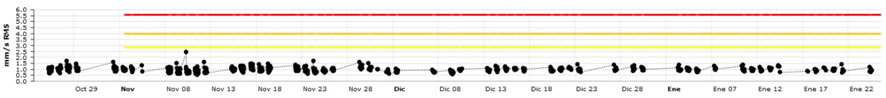

The main feature of online monitoring is the continuous and permanent measurement of vibrations through sensors strategically installed in the rotating equipment to detect any possible failure in time, saving not only on repair and corrective maintenance costs, but also increasing the profitability of installation by making the most of the remaining useful life of the machines. In addition to being automated, it is remote.

A breakdown evolves until it becomes catastrophic. If we detect it in time before its evolution, we can plan and carry out the appropriate corrective measures, making staff planning and the provision of spare parts more efficient. A better understanding of the failures, in time, will help us in identifying the improvements that we can introduce to increase the useful life, or at least to minimize the adverse consequences of the failures in the production and safety of the installation.

At Talleres Haizea SL we advise you, we work with highly specialized personnel and state-of-the-art electronics.